Metalwork, Precise As A Clockwork

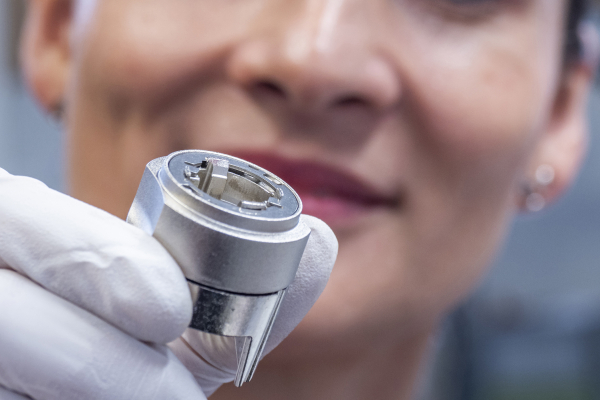

We are your reliable partner for high-precision deep-drawn parts and assemblies made of metal. Our products meet the demanding requirements of renowned companies in the automotive supply industry, measurement, control, and automation technology, as well as many other sectors. To remain successful in the market permanently, we rely on long-standing and sincere relationships with our employees, customers, suppliers, and business partners.

We offer a comprehensive, custom service, starting with the collaborative brainstorming for your products. Our services include design, tool and fixture construction, prototyping, pre-series production, and large-scale production using state-of-the-art multi-stage forming presses and follow-on composite tooling. Additionally, we offer various surface treatment processes, heat treatment, and assembly of components.

With more than a century of experience in deep-drawing technology and a team of carefully selected experts, we always ensure to meet the requirements of our steadily growing customer base to their fullest satisfaction.

Our Client Relationships.

We maintain long-term and trustful business relationships with our international customer base, characterized by respect and appreciation. Some of our business partners have been with us for more than 50 years, on a shared journey that continuously adapts to the constant changes in culture, economy, ecology, and technology. Meeting the increasing requirements of the market sets us apart from our competitors and enables us to regularly establish significant and forward-looking new partnerships.

Our Materials Are Malleable. Our Morals Are Not.

We focus on flawless precision, innovative thinking, a strong sense of quality consciousness, and constant flexibility. From consultation to production-ready component concepts, we provide all necessary services from a single source. Starting from prototyping, through design and tool manufacturing, to series production of deep-drawn parts and assemblies.

Our daily goal is to produce high-quality products precisely tailored to their respective applications. By innovation, we understand not only technological advancement but also meaningful improvements from economic and ecological perspectives.

Behind this approach are reliable and long-standing business relationships, alongside expertise and entrepreneurial passion. This forms the basis of a great guiding principle that we live by every day. The crucial aspect is the added value from which our customers benefit.

Precision. Innovation. Quality. Flexibility.

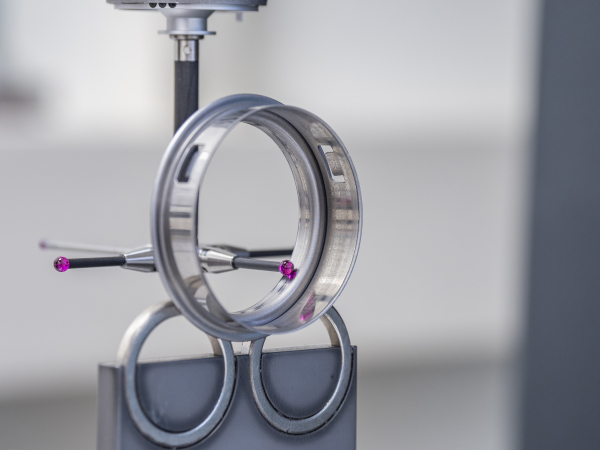

Our intelligent quality management creates significant added value for our customers. A comprehensive CAQ system provides maximum transparency from incoming goods to delivery. We pursue a holistic quality standard and ensure sustainable business practices in all areas of the company – from requirement capture to requirement fulfillment. This encompasses products, services, processes, and organization. In product development, all quality-relevant aspects such as critical features, measurement technology, part handling, and packaging requirements are incorporated into the component concept.

We maintain active management systems in accordance with ISO 14001. Since 1998, our quality management has been certified according to ISO 9001 and firmly integrated into daily work routines. In 2005, certification according to TS 16949 followed, and in 2018, according to IATF16949. Our goal is to consistently evolve products and processes and to seamlessly secure requirements in production. Together with our customers, suppliers, and employees, who are daily aware of their responsibility through identification with the products, we consistently strive for the goal of "Zero Defects.“

Shaping The Future – Our Company Goals

Our top priority is long-term success in the market through excellent service and high-quality products that solve real problems. These fundamental principles form the basis for sustainable returns, continuous growth, and the ongoing development of our company.

The constant expansion of existing markets and the exploration of new application areas enable this positive development. Openness to new products and processes helps us to effectively combine attractive market opportunities with existing competencies and optimize our growth potential.

Unity Made Of Steel – Our Team

The success of our company is primarily due to our employees – the performance, commitment, and reliability of each individual. To ensure the long-term satisfaction of our employees, we create individually tailored working conditions and promote professional qualifications and development.

Training young talents is a key aspect for us in sustainable team building and strengthening the entrepreneurial future. Thus, we are already laying the groundwork for the next 100 years of OEKATECH.

Our Suppliers

We value our suppliers and have maintained collaborative relationships with them for decades. Through open and trusting communication, they support us in our daily endeavor to flexibly meet the needs of our customers.

Together, we optimize our processes on both sides and find better economic and technical solutions. The long-term development and qualification of our partners are paramount and are an important foundation of our success.

Business thrives when the environment flourishes.

We emphasize environmental responsibility in all our business processes, from production to administration, supported by our environmental and energy management system. Already in product development, we focus on resource-saving solutions and offer to replace material- and energy-intensive turned and die-cast parts with more environmentally friendly deep-drawing solutions. Where possible, we direct waste to the recycling process and ensure the proper disposal of non-recyclable materials. We avoid waste, whether through overproduction, scrap, or unnecessary transportation and storage.

The use of environmentally harmful substances is minimized, and we handle them carefully. To avoid environmental impact, we assess existing and new activities, procedures, products, and services for their environmental friendliness. We also place great importance on our supply chains in this regard. There is no part of the operation that is not checked for its environmental impact. Our quality and environmental objectives are represented, pursued, and monitored by the management. The leadership style should serve as an example and provide assistance to employees in quality and environmental protection matters. These goals are achieved through a well-organized management system, as documented in the management manual.

Advanced Metalwork For Over 100 Years – The Company History

In 1914, the toolmaker Georg Oehlhorn and the merchant Sally Kahn founded the "Neue Metallwarenfabrik Bamberg – Oehlhorn & Kahn," which focused on the production and distribution of stamped, bent, and deep-drawn parts for the technical industry. Over the years, the company evolved:

1928: The commissioning of the first stage press marks a milestone for productivity.

1960: The expansion of construction and toolmaking enables the continuous development of deep-drawing technology.

1972: The use of stainless deep-drawing steels and increasing precision lead to the expansion into the automotive supply market.

1988: Expansion of the machinery allows for the production of significantly larger and more complex deep-drawn parts.

2003: The automotive supply industry becomes the second major pillar, with investments in a multi-stage forming press with higher press force.

2014: Rebranding to "OEKA" creates three separate market segments: OEKAtech, OEKAbeauty, and OEKAmed.

2015: GEKA GmbH acquires OEKA, integrating OEKAbeauty and OEKAmed into the structure, while OEKAtech continues as an independent entity named OEKA TECH Automotive GmbH.

2016: OEKA TECH Automotive GmbH is acquired by the Munich-based investment company RCP and continues as an independent entity, focusing on metal forming and deep-drawing technology.

2020: The company positions itself for the future by optimizing and developing thin-walled deep-drawn parts for applications in sensors and electric drives. This segment is expected to contribute significantly to future revenue.

2022: Bei der OEKA TECH stehen weiter die Zeichen auf Wachstum und zukunftsgerichtete Technologien. Wir investieren in einen modernen 200 to. Hochleistungsstanzautomat, unter anderem für den wachsenden Markt der Airbagfertigung.

2023: Wir erweitern unsere Fertigungstiefe durch den Kauf einer vollautomatischen Laserschweißanlage für Nirostabauteile. Darauf werden unter anderem Komponenten für das autonome Fahren verschweißt.

2024: OEKA stärkt den Bereich Non-Automotive durch die Aquisition eines Neukunden im Bereich Sicherheitsschließsysteme - bald gibt es mehr Infos hierzu!

Our Location: Living and Working in the UNESCO World Heritage Site Bamberg.

Welcome to Bamberg, a city of exceptional beauty and diversity! With its status as a UNESCO World Heritage Site, Bamberg is not only a cultural treasure but also one of the most family-friendly medium-sized cities in Germany, as confirmed by the recent ZDF/Prognos study.

Situated in the picturesque Regnitz Valley, surrounded by the natural reserves of Franconian Switzerland, Steigerwald, and Hassberge, Bamberg offers an attractive environment for leisure activities after work. The culinary scene is impressive, from daily markets to family-run breweries producing over 400 different beers. You'll be delighted by Franconian cuisine with specialties such as "Bamberger Hörnla" and "Schäuferla." Bamberg has something to offer for every lifestyle. In addition to numerous opportunities for active leisure activities in the city and beautiful nature, there is a wide range of music events, theaters, and cabaret stages. Events like the "Sandkerwa," "Bamberg zaubert," the "Bamberger Biertage," the "Jazz and Blues Festival," and the "Weinfest Schloss Geyerswörth" bring the historic city center to life.

Bamberg is excellently connected in terms of transportation. Within just under two hours, you can reach Munich, and in just under three hours, you can reach Berlin - directly and without changing trains thanks to the excellent ICE network of Deutsche Bahn. Local trains run hourly to Würzburg, Nuremberg, and Bayreuth. Highways A70 and A73 provide direct access to the federal highway network, and Nuremberg Airport is only a 40-minute drive away. The major airports in Munich and Frankfurt can be reached in about two hours. Within Bamberg, there is also an extensive network of public transportation available.

See you soon in Bamberg, a city that combines history and modernity in perfect harmony and offers an incomparable living environment. We would be delighted to welcome you as a new member of the OEKATECH family soon!